KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

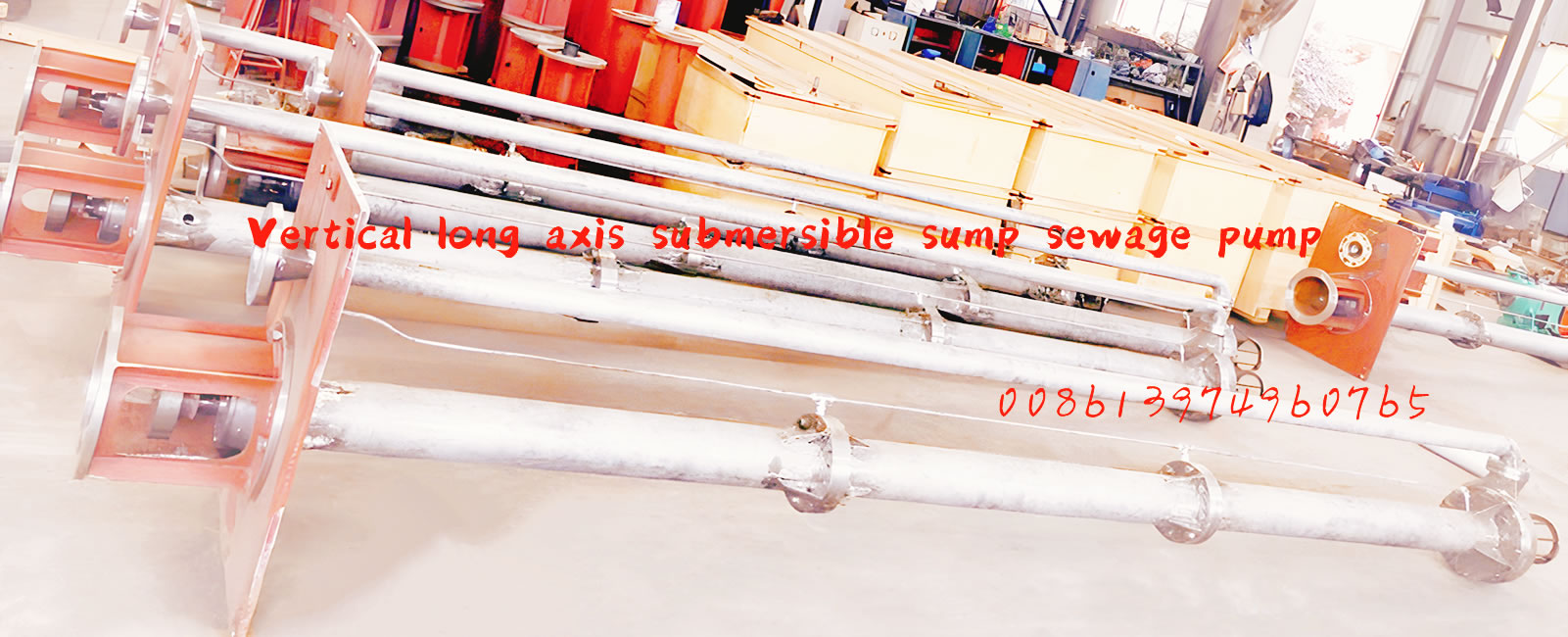

Suitable for the installation of suspended semi submersible vertical turbine pumps in marine ship engineering

A fixture suitable for the installation of suspended semi submersible vertical turbine pumps in marine ship engineering, characterized in that it comprises a frame body. The upper end of the frame body is welded with channel steel 1, and the lower end support foot is welded with a flat bottom plate. The channel steel is welded with two sleeves, and each sleeve is equipped with a solid upper and lower oil support top wire rod. The upper end of the solid upper and lower oil support top wire rod is welded with a V-shaped support plate, and two universal balls with bolts corresponding to the positions are installed on both sides of the V-shaped support plate. This technical method provides a tool for adjusting the screw type support universal ball tire frame, which is suitable for the assembly of suspended semi submersible vertical turbine pumps and multi-stage axial assembly equipment. It prepares for installation, effectively reduces labor costs, saves resources, improves efficiency, and enhances the convenience and systematicity of on-site installation and management. It is necessary for the marine ship engineering industry to adopt this universal ball fixture to reduce the investment of on-site construction manpower and the use of crane resources.

Technical requirements: 1. A fixture suitable for the installation of suspended semi submersible vertical turbine pumps in marine ship engineering, characterized by comprising a frame (2), wherein the upper end of the frame (2) is welded with a channel steel (1), and the lower end support foot is welded with a flat bottom plate (3). The channel steel (1) is welded with two sleeves (6), and each sleeve (6) is equipped with a solid upper and lower oil support top wire rod (5). The upper end of the solid upper and lower oil support top wire rod (5) is welded with a V-shaped support plate (4), and two corresponding positions of multi-directional balls (7) with bolts are installed on both sides of the V-shaped support plate (4).